Sensors

Amphenol is a leading innovator in sensor technologies and measurement solutions. We offer the most diverse sensor portfolio of standard and customized products for the world’s most demanding regulatory and industry-driven applications. Our products and technologies include temperature sensors, moisture meters and sensors, pressure sensors, thermal validation sensors, position sensors, vibration sensors, ultrasonic sensors, level sensors, quality sensors, force sensors, acoustics sensors and magnetostrictive linear position sensors.

Visit our Amphenol Sensors site to learn more.

150WXRS WeatherStation® Instrument

Airmar’s WeatherStation WXRS provides real-time information on rain intensity, accumulation, and event duration. An acoustic sensor measures the impact energy of individual raindrops on the top of the instrument. This patented rain-detecting sensor is virtually maintenance-free. It has no moving parts or components that need to be emptied, cleaned, or will become clogged by debris.

150WXS WeatherStation® Instrument

Airmar’s WeatherStation 150WXS provides accurate, site-specific, weather data from a single compact device. It measures seven critical weather parameters in real-time. The compact housing features ultrasonic wind and barometric pressure measurements. Plus the solar radiation shield increases the stability of temperature and relative humidity readings.

200WX WeatherStation® Instrument

The WeatherStation 200WX is the best choice for mobile or stationary, weather-monitoring applications. Sensor rich, in a durable, rugged, small housing that is IPX6 rated, means the 200WX can be used on moving platforms such as TV-news and military vehicles. The 200WX calculates the dynamic true wind speed and direction based upon the apparent wind speed of the vehicle, and vehicle heading.

746 General Purpose Underwater Accelerometer

The 746 underwater accelerometer withstands continuous submersion to 650 PSI. The lightweight titanium case is resistant to galvanic corrosion and offers strong performance at high pressures. A potted integral cable prevents water ingress and protects the circuitry. The 746 is used for ship propulsor and hull vibration monitoring, acoustic signature monitoring on submarines, and lab research.

754 Miniature Underwater Accelerometer

The 754 underwater accelerometer withstands submersion to 650 PSI. The lightweight titanium case is resistant to galvanic corrosion and offers strong performance at high pressures. A potted integral cable prevents water ingress and protects the circuitry. Applications for a 10 mV/g high amplitude sensor include intrusion detection, propulsion system diagnostics, and acoustic signature reduction.

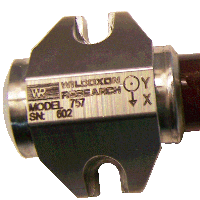

757 Biaxial Underwater Accelerometer

Wilcoxon’s 757 biaxial underwater accelerometer withstands continuous submersion to 650 PSI. The potted integral cable prevents water ingress and protects the circuitry. A stainless steel overbraid prevents cuts, abrasions, and damage to the integral cable. Multidirectional vibration analysis is ideal for low-frequency monitoring of ship propulsion systems and hydroelectric power gen.

883M Digital Triaxial Accelerometer for Industrial IOT

Our industrial triaxial accelerometer and temperature sensor with Modbus output enables data sharing with local and plant data systems, including PLCs, DCSs, SCADAs, and HMI displays. More than 50 calculated vibration metrics, vibration spectrum, and time waveforms empower operators with digital data for condition monitoring, process monitoring, IoT edge processing, and data science activities.

Accelerometers for Monitoring Wind Turbine Health

Vibration diagnostics find the root cause of problems and establish a baseline of wind turbine health to avoid unplanned outages and expensive unscheduled repairs by identifying problems, providing early warning of fault conditions, and preventing catastrophic damage to turbines, gearboxes, bearings, main shafts, and towers.

Accelerometers for Oil & Gas Machinery and Equipment

Safely monitor the health of machinery in oil and gas operations with vibration sensors and vibration transmitters rated for operation in hazardous locations and high-temperature environments, including offshore, petrochemical, refineries, and chemical processing: blowers, centrifuge, chillers, compressors, cooling towers, fans, gearboxes, mixers, motors, pumps, turbines, and vibrating conveyors.

Accelerometers for Rail Car Wheel and Locomotive Health Monitoring

Vibration monitoring identifies wheel problems, mechanical faults, or component wear and helps rail operators schedule repairs, analyze/sustain rail equipment life, avoid expensive damage, and operate safely and reliably. Monitored railway assets include cab, trucks, wheel bearings, wheel drive motors, main engine, diesel engine, gearboxes, generators, head-end power unit, and roller elements.

Air-In-Line Ultrasonic Bubble Sensors

With over 20 years of experience, Piezo Technologies is the premier designer and manufacturer of smart ultrasonic air bubble detectors for the medical infusion industry and enteral nutrition delivery. Industry-leading piezoceramics and in-house transducer engineering ensure custom ultrasonic air-in-line sensors meet the highest standards for quality, performance, and reliability. ISO 13485 certified.

AT200 Airducer® Ultrasonic Transducer

The AT200 delivers unparalleled ultrasonic sensing performance with level, flow, distance, proximity and object detection measurement applications. It includes rugged sealed construction, and PVDF housing is available for more chemically aggressive environments. The AT200 operates at 200 kHz and its sensing range is 10 cm to 3 m.

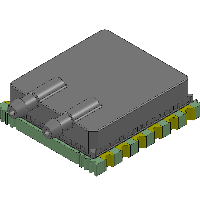

AUAV Pressure Sensor Series

The AUAV Series is a dual-sensor solution for UAVs, combining a high-accuracy differential pressure sensor (airspeed) and a barometric pressure sensor (altitude) in one compact package. Dual ASIC compensation enables 18-bit precision for simultaneous airspeed and altitude measurement in drone and aerospace applications.

Combined Pressure & Temperature Sensors

i2s is your contact for the development and production of pressure sensors, temperature sensors, mass air flow sensors, as well as combination sensors for several measurements. Customers from the automotive, commercial vehicle, mechanical engineering, and metrology industries have been relying on our experience and know-how for more than 15 years.

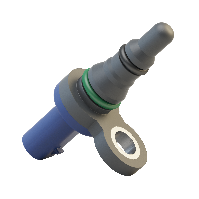

Coolant Temperature Sensor

Temperature sensors are used to measure media temperatures or body temperatures at various points in the vehicle. These sensors can be either individual sensors or integrated with other components or liquid ducts.

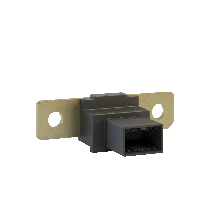

Current Sensors

The measurement of currents in the power train is essential, e.g. for monitoring and controlling the drive power. We offer current sensors in different versions, with one or more current paths and with or without integrated temperature measurement.

Current Sensors

Piher Sensing Systems designs and manufacturers current sensors based on contactless technology for accurate measurement of currents in automotive battery management and motor control applications.

Piher’s precision current sensors improve motor or solenoid control applications and grid monitoring addressing the needs of both Tier 1 suppliers and OEMs.

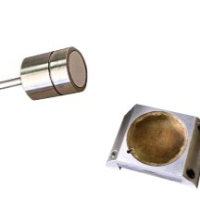

Custom Design & Development of Ultrasonic Transducers

Piezo Technologies assists customers in designing, developing, manufacturing, assembling, and testing a wide range of custom piezoelectric ultrasonic transducers. We specialize in solving complex ultrasonic transducer challenges and have extensive experience designing and manufacturing high temperature, high pressure, and harsh environment transducers.

Custom Hemispherical and Spherical Piezoceramics

Piezo Technologies specializes in designing, modeling, and developing hemispherical and spherical piezoelectric ceramic sensing elements for customers who range from prime defense contractors to naval labs and advanced marine research teams. Some require only the ceramic, custom-shaped to exacting frequency, sensitivity, and depth specifications. Others ask us to build the entire transducer.

Custom Piezoceramic Composites

Piezo Technologies’ custom piezoceramic composites offer improved and tunable acoustic matching, higher bandwidth, and faster ringdown characteristics, compared to traditional piezoceramics. Applications include underwater sonar, handheld sonar, underwater buried object detection, and NDT. We can provide custom sensing elements as well as complete build-to-spec ultrasonic transducers.