Cable Assemblies

Amphenol’s cable assemblies include simple point-to-point cables, custom high-power and high-speed data cable assemblies and complex multi-branch harness assembly for large systems across a broad range of end markets. Our cable assemblies include the latest industry innovations in radio frequency (RF), fiber optics, high-power requirements and high-speed data transfer for the newest systems and applications. In addition, our broad portfolio of cable connectors and accessories can be used in our cable assemblies to provide a complete solution.

View our businesses providing Cable Assemblies solutions.

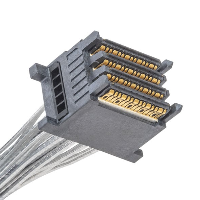

DSFP Cable Assemblies

Amphenol's DSFP cable assemblies are designed to support applications for Ethernet and Fibre Channel. The Amphenol DSFP products offer an ultra-high-performance, cost effective solution for 10G/25G/50G speed applications in switched fabric I/O, switches, routers, data storage arrays, and high-performance computer (HPC) clusters. The Small Form Factor Pluggable (SFP) interface supports a variety of commun...

EDSFF E1/E3 High-Speed Cable Assembly

EDSFF ORTHOGONAL CABLE ASSEMBLY WITH DIFFERENTIAL SIGNALING TO 32GT/S NRZ FOR NEXT-GENERATION SYSTEMS

Amphenol's EDSFF E1/E3 high-speed cable assembly transmits power and high-speed signals via a cable that directly connects to the main PC board supporting EDSFF E1/E3 SSD and CXL or other modules.

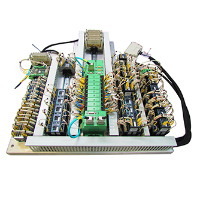

Electrical Plates

Electrical plates for busses, electrobusses, trolleybusses, railway vehicles, including fuses, circuit breakers, relays, and ECUs connected by wire harnesses.

Electrophysiology

Bernd Richter GmbH offers highly flexible catheter cables designed for sensitive cardiology applications such as electrophysiology. These cables combine exceptional durability with extra-small bending radii, low-noise performance to minimize interference, and materials that meet strict biocompatibility and cleanliness standards—ensuring reliable function in critical clinical environments.

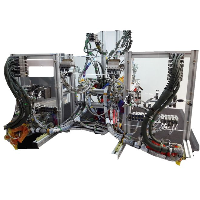

eMobility Harness & Components - India, North America and Europe

Interconnect products for eMobility applications: HV/HP connectors, interfaces, cable assemblies, bus bars, MSD, vehicle inlets, PDUs, and customized interconnect solutions. Compact low-voltage and high-voltage harness solutions meet demands up to 1000 V DC and 450 A.

Engine & Ancillary Components

Connecting Cable for Engine Cooling - The connectors, including the seal, are automatically over-moulded in production cells with lead frame and liquid silicone LSR. Special process steps create the connection to the lead frame, strain reliefs, and longitudinal water tightness.

EWIS Harness Electrical Wiring & Interconnect System.

EWIS Harnesses are designed to make the connection of Low Voltage Signals, Power Distribution, RF signals <2GHz, and Fiber Optic; in pressurized or unpressurized sections; in-cabin, cockpit, avionic bay, or even on Space applications. We hold Part21G and PART145 certificates for production and maintenance. We support product design and certification by delivering full documentation.

EXAMAX2® 112Gb/s Backplane Cable

EXAMAX2® Cable Backplane Systems offer high density cable assemblies for both internal and external applications that are capable of delivering high speed performance of 112Gb/s per channel. EXAMAX2® cable applications include internal OverPass™ cables, external I/O cables, cabled midplane and cabled backplane

ExaMAX® 56Gb/s Backplane Cable

The ExaMAX® I/O system offers cable assemblies and I/O connector solutions for both internal and external applications. ExaMAX® I/O products are capable of delivering high-speed performance of 25 Gb/s per channel with a path to 40 Gb/s and higher. The ExaMAX® I/O system delivers superior linear board signal density and meets the performance requirements of the OIF-CEI-25G-LR industry standard.

Exhaust Cleaning Harness

Exhaust Gas Sensor - Signals are transmitted between NOx sensors and control electronics using our connection system. Special contact and housing materials are able to resist high exhaust-gas temperatures. By developing our own systems, we achieve low and steady contact resistances, which are needed for the transmission of sensor currents.